What is a custom roof rack install and how does it work?

For canopies and tub hard lids that don’t easily fit with out-of-box rack components, a custom install may be the best option.

There are three types of materials that allow for custom installs – metal, fibreglass and UV-stable ABS (a thermoplastic polymer).

A roof rack system can be attached by the following methods:

- Tracks – on fibreglass, ABS or metal surface canopies or hard lids

- Permanent Mount – on fibreglass, ABS, metal canopies or hard lids

- Artificial Raingutters – on fibreglass, ABS or metal canopies (DO NOT fit Artificial Raingutters on hard lids)

Custom roof rack installation

Custom installs can be done by a non-qualified professional roof rack installer (DIY), but this would be at your own risk. We do not recommend drilling into your vehicle if you are not sure what you are doing; although it may not seem not difficult with the right tools, mistakes can be costly.

Because of the varied nature of the installs, we are unable to provide exact drilling instructions. It is up to the installer to determine the exact location of roof rack placements on the vehicle.

In some cases, the hard lid or canopy will have a strengthened section that is meant to carry a load through a roof rack system. These strengthened sections are pointed out by canopy and hard lid manufacturers.

If you are still unsure of where to mount the roof racks, it would be best to find a find a local Prorack dealer who does these types of installations, or to contact a local body shop, most can perform this type of work.

If you still choose to do the installation yourself, we recommend following these guidelines:

- Contact the canopy or hard lid manufacturer to provide information about the integrity of the roof or surface (weight capacity, strengthening ribs, etc.) for your purposes.

- Avoid drilling in spots where there may be interference with wiring, roof vents or internal brackets and bracing.

Types of custom roof rack install fits

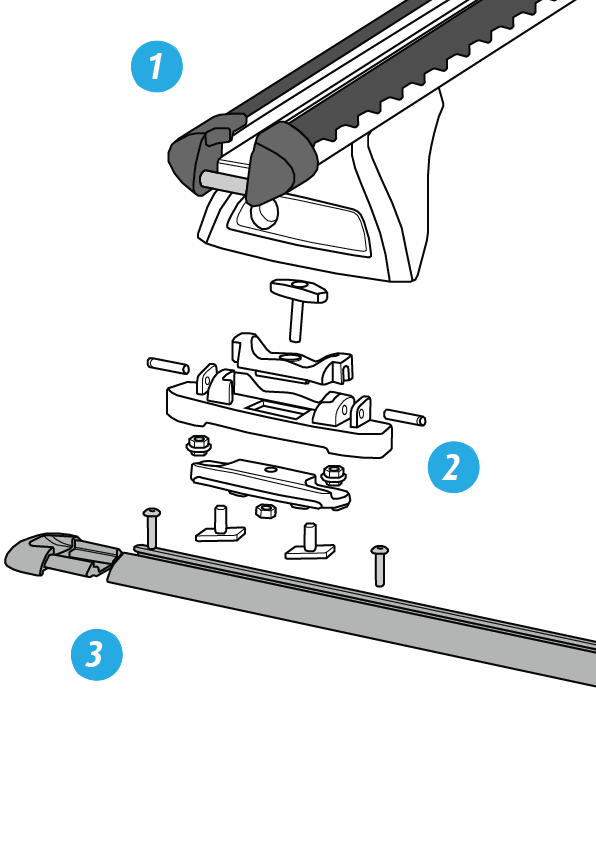

Tracks for fibreglass, ABS or metal surface canopies on hard lids

Aluminium tracks are installed to the roof of your canopy or hard lid via rivets or fasteners through pre-drilled holes. The tracks come in different lengths to suit the application. Roof racks attach to the tracks, allowing for easy adjustment and removal.

To determine the length of track, measure the flat part of the surface and deduct 120 mm to allow for the two end caps.

Track fits are:

- Suitable for flat surfaces and allows for roof rack spread variation

- Able to be paired with Proack Aero, Heavy Duty or Standard Bars using fitting kits K450 or K327

- Available in sizes 80 cm to 200 cm

Example of Prorack Heavy Duty bars to Tracks

- Heavy Duty Bars (various lengths available)

- Fitting Kit (K450)

- Universal Tracks (various lengths available)

PLEASE NOTE: If using Q20, K450 is NOT required.

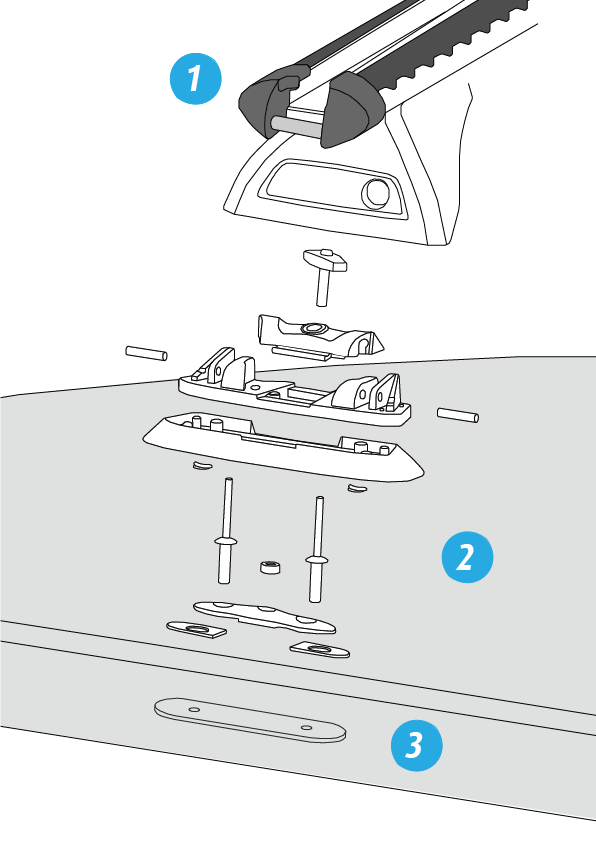

Permanent mount on fibreglass, ABS or metal canopies or hard lids

Four small holes (per roof rack bar) are drilled into the roof of your canopy or hard lid. The threaded anchor point is then riveted in place to the roof through these four small holes and a roof rack is attached to those anchor points.

Permanent fits are:

- Suitable for flat or curved surfaces

- Able to be paired with Prorack Aero, Heavy Duty or Standard Bars

- For use on metal, fibreglass or ABS canopies and hard lids

PLEASE NOTE: The PR3070 (Canopy Adaptor Kit for K323) is required for fibreglass, ABS, aluminium canopies and hard lids. PR3070 is not needed for metal roof installations.

Example of Prorack Heavy Duty bars to Permanent Mount

- Heavy Duty Bars (various lengths available)

- Fitting Kit (K323)

- Canopy Adaptor Kit (PR3070) strengthening plate

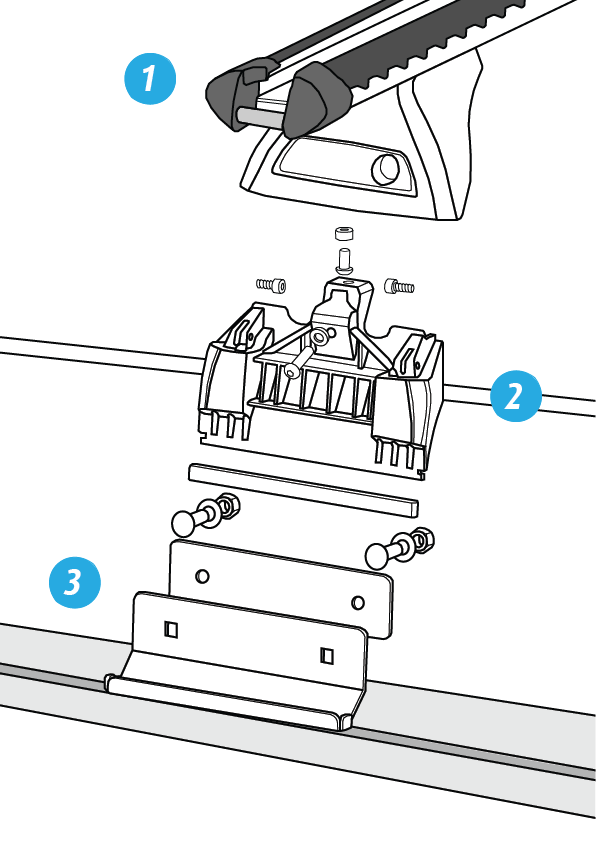

Artificial rain gutters on a fibreglass, ABS or metal canopies (DO NOT fit on hard lids)

A custom installed artificial rain gutter is specifically developed to allow the mounting of roof racks to the side of canopies. Four small holes (per roof rack bar) are drilled into the side of your canopy, gutter brackets are bolted on via the drilled holes and gutter-type roof racks are then fitted onto these brackets.

Artificial rain gutter fits:

- Are able to be paired with Prorack Aero, Heavy Duty or Standard bars using Fitting Kit K324

- Can be useful for levelling up roof rack height between cab and canopy

Example of Prorack Heavy Duty bars to Artificial Rain Gutters

- Heavy Duty Bars (various lengths available)

- Fitting Kit (K324)

- Artificial Rain Gutters (TAARG 1x kit per crossbar)

Height Packers

Height packers may be required in the following instances:

1. A Hard Lid with a raised centre that the roof rack needs to be lifted to clear

Example of Prorack Heavy Duty bars fitted to a Track and raised using Height Packers

- Fitting Kit (K450)

- Universal Tracks (various lengths available)

- Heavy Duty Bars (various lengths available)

- Heavy Duty Bar Height Packer Kits

PLEASE NOTE: If using Q20, K450 is NOT required.

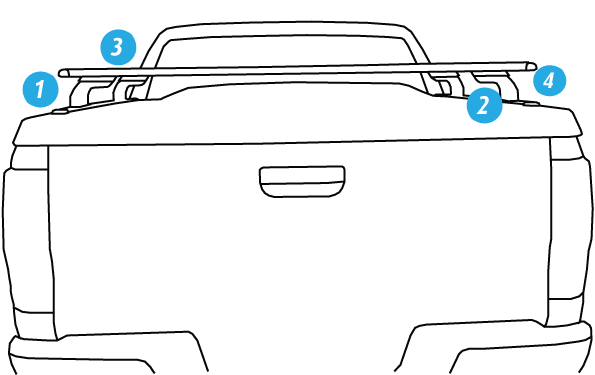

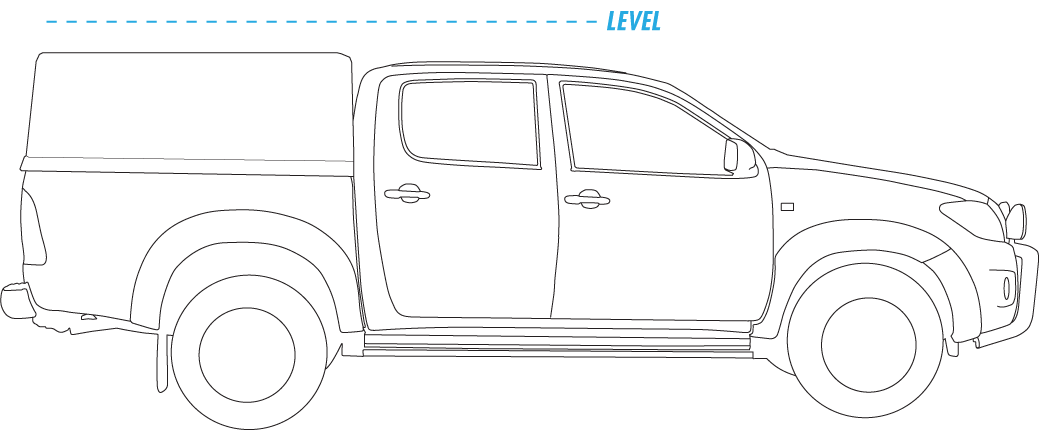

2. When three or more roof racks are fitted to a vehicle and canopy

When three or more roof racks are fitted to a vehicle and canopy, it is highly recommended to level the roof racks on the vehicle. This can be done using either height packers orartificial rain gutter mounts. Only Prorack Heavy Duty Bars can be raised using Prorack Height Packers.

Example of Prorack Heavy Duty bars fitted to a vehicle and canopy using Height Packers to level the bars to one another

Each height packer increases the bar height by 7.5 mm increments. A maximum of four height packers can be used per leg (eight per Roof Rack).

Prorack Heavy Duty Height packers are sold as shown in the table below.

|

SKU |

PRODUCT NAME |

DETAILS |

|---|---|---|

|

TP1 |

Provides one Heavy Duty bar with 7.5 mm increase in height |

|

|

TP2 |

Provides one Heavy Duty bar with 15 mm increase in height |

|

|

TP3 |

Provides one Heavy Duty bar with 22.5 mm increase in height |

|

|

TP4 |

Provides one Heavy Duty bar with 30 mm increase in height |

Australia

Australia  New Zealand

New Zealand

Find my Car

Find my Car